Research Projects

X-ray LINe Detector with novel photon counting ASIC (LINDA)

LINDA

X-ray LINe Detector with novel photon counting ASIC (LINDA)

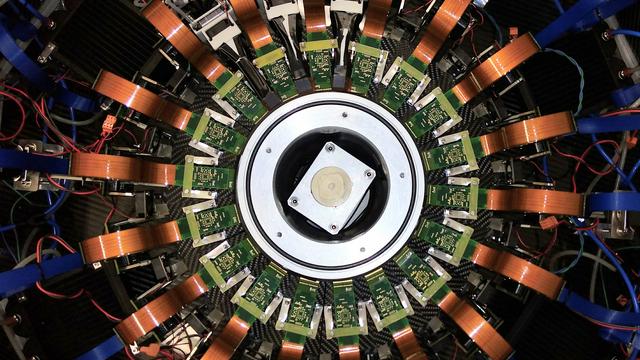

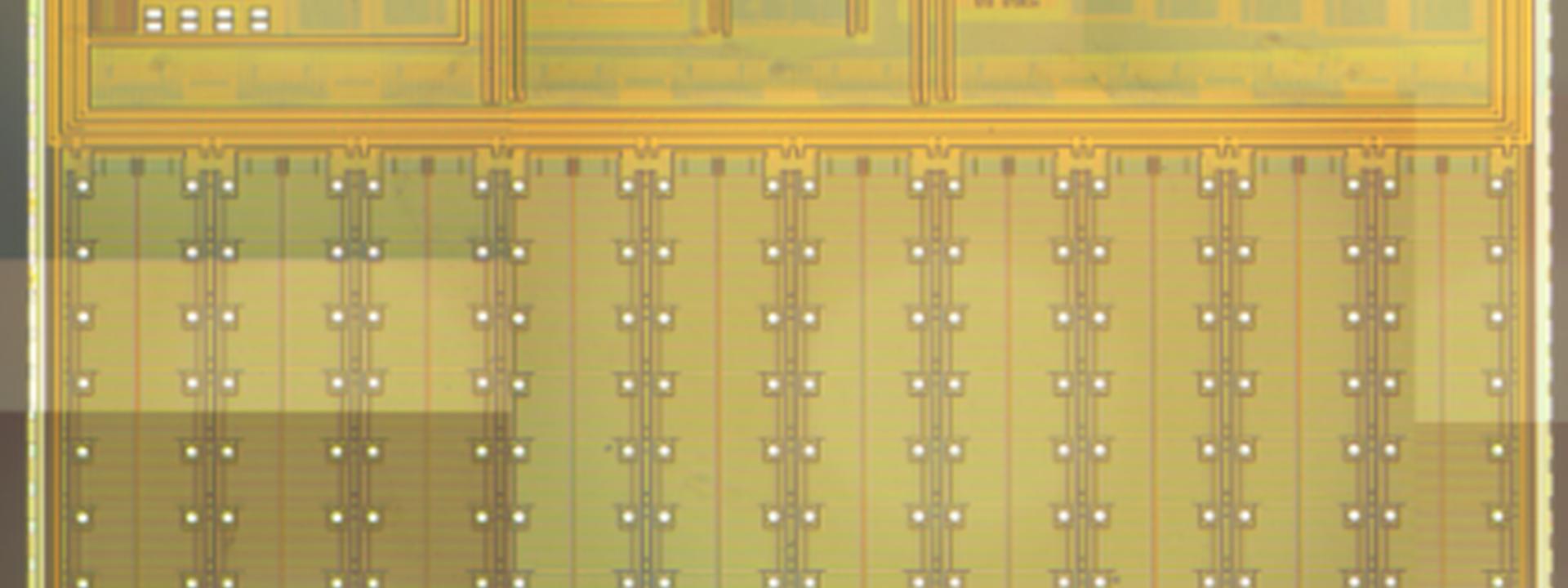

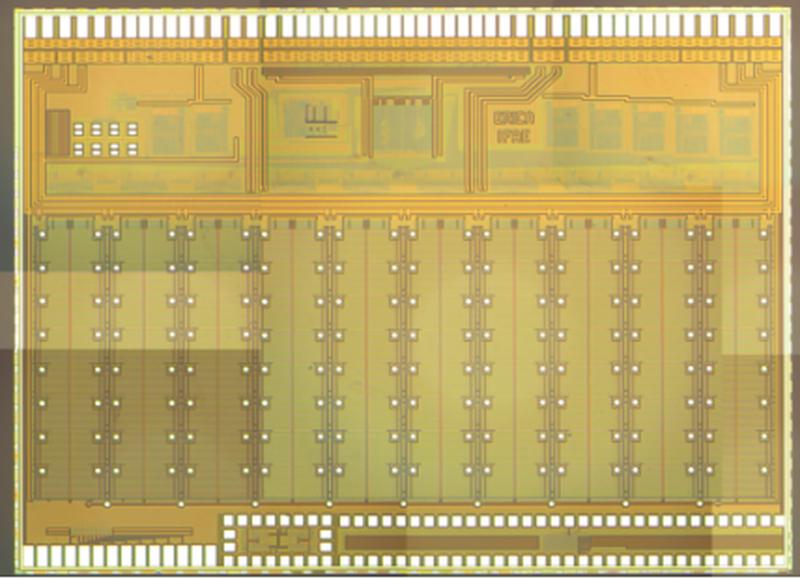

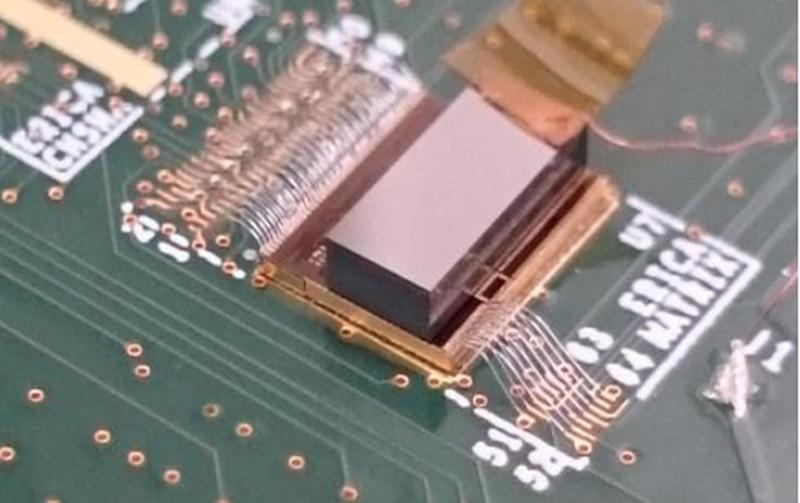

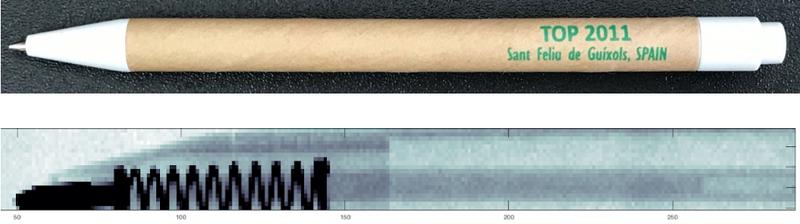

LINDA (X-ray LINe Detector with novel photon counting ASIC) is a pixel CdTe sensor with a built in fast algorithm (patent protected) to minimize the charge sharing among neighbouring pixels and thus maintains the spectral X-ray energy information per pixel. Each pixel has 6 thresholds to bin the spectral energy information into 6 levels. Each energy level has two counters one to read and one to acquire data so that the detector has zero dead time. One can see in fig.1 the kernel sensor of the of the X-ray line detector. The active size is 2.64 mm x 6.6 mm. When a number of such sensors are put side by side they will form a line detector that matches the scanner´s field of view.

Fig2 shows the results obtained using one LINDA sensor. One can see clearly the internal elements inside the pen. The image has not been subjected to image processing. Though the LINDA sensor is made for X-ray line scan machine, It can be tailored to fit the needs for the future Spectral Computed Tomography Scanner.

The LINDA sensor is unique because it has a fast algorithm to reduce the impact of the charge sharing process and thus preserve the spectral energy information detected. The preliminary report from the European Patent Office acknowledges the innovative steps in the charge summing mode for X-ray pixelated detector. At same time the LINDA sensor has relatively small pixel size (330um x 330um) for this type of application and with zero dead time. That is the sensor can acquire and send data simultaneously without loss of information. Given the LINDA sensor is an array of 8 (in direction of the moving belt) x 20 pixels this implies that object get imaged 8 times, by the 8 pixels as the object mover on the belt, and this provide a better image quality. This technique is called Time Delay Integration (TDI). With current version of LINDA sensor, one can achieve a scan speed of 20 m/min.

The team of researcher will develop a 20cm X-ray line scanner based on LINDA sensor, which will be integrated into an X-ray machine provided by Multiscan Technologies SL.

This project has been co-financed by the European Union through the European Regional Development Fund (ERDF) and Agència de Gestió d’Ajuts Universitaris i de Recerca (AGAUR), and has been supported by the Secretaria d’Universitats i Recerca of Departament d’Empresa i Coneixement of Generalitat de Catalunya.

This algorithm has been filed as a patent application granted in China and the EU in 2018 and 2019, respectively, and expected to be granted soon in Japan.

The project aims to build a 20 cm long line camera and to test it in a commercial X-ray scan machine used for food quality control by summer 2021. In 2020, LINDA was submitted to The Collider program, by Mobile World Capital, and was one of five proposals selected for funding, out of 100+ applications. The Deep-Detection start-up company has been recently constituted to exploit this technology.